February 2018

For those born missing fingers or hands or who have lost them due to various circumstances, it can be difficult to live a normal life. Wrist flexion and extension enables people to perform daily activities, such as playing sports, eating with utensils, and putting on clothes.

Our challenge for Apollo was to design and model an improved prosthetic hand and arm for children that incorporates an extension based hand grip mechanism while maintaining a user-friendly design. Our design enables grip in a hyperextended motion to enable children to live a normal life.

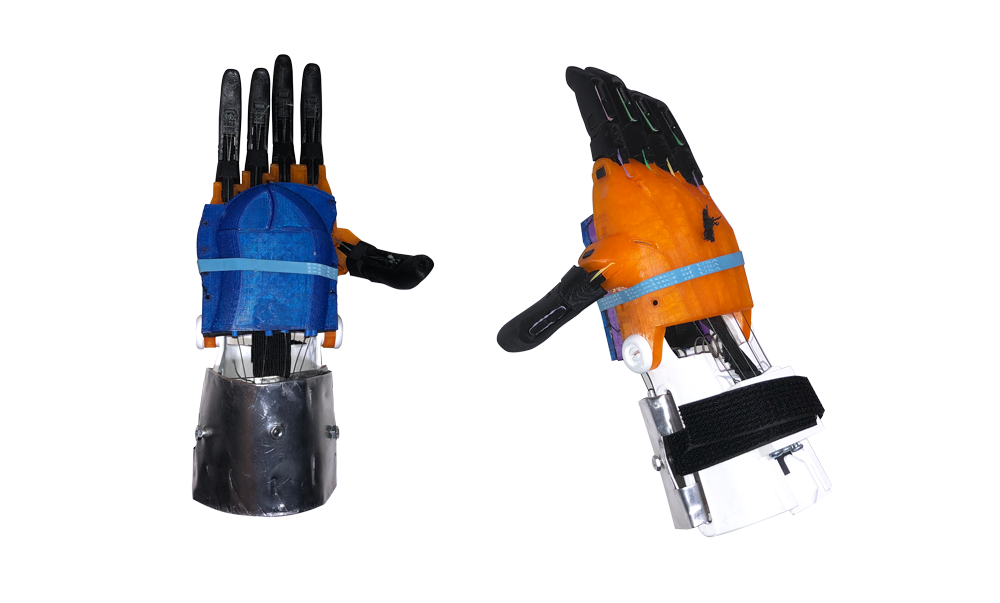

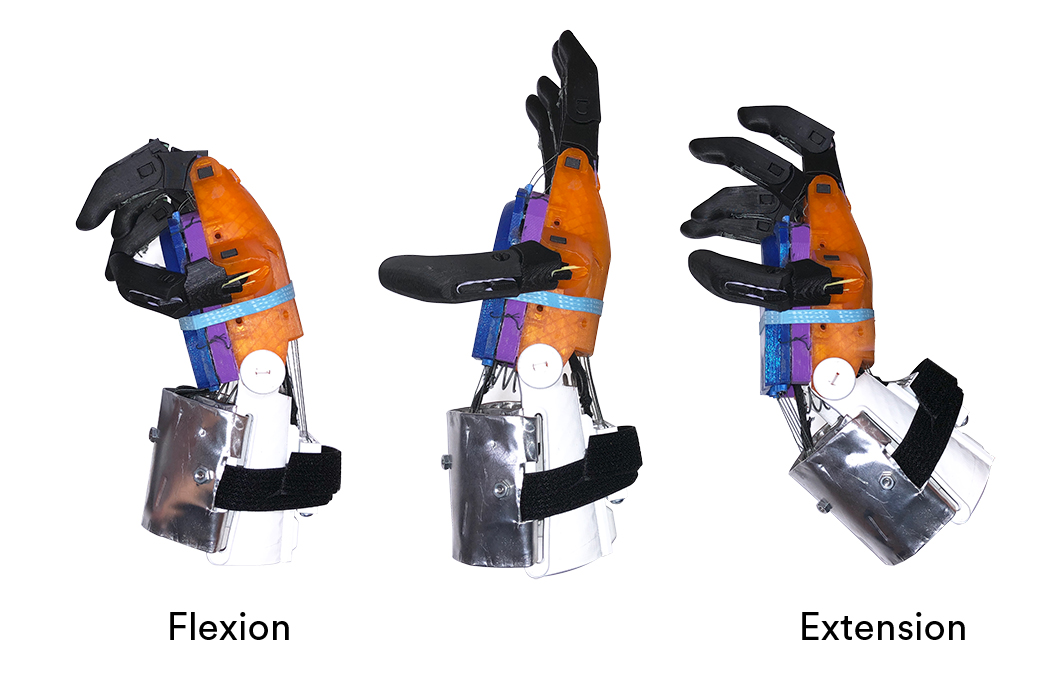

Design incorporates flexion and extension, as labeled above.

As part of the Associated Students of Biomedical Engineering's makeathon competition, my team had 48 hours to design and present a functional prototype.

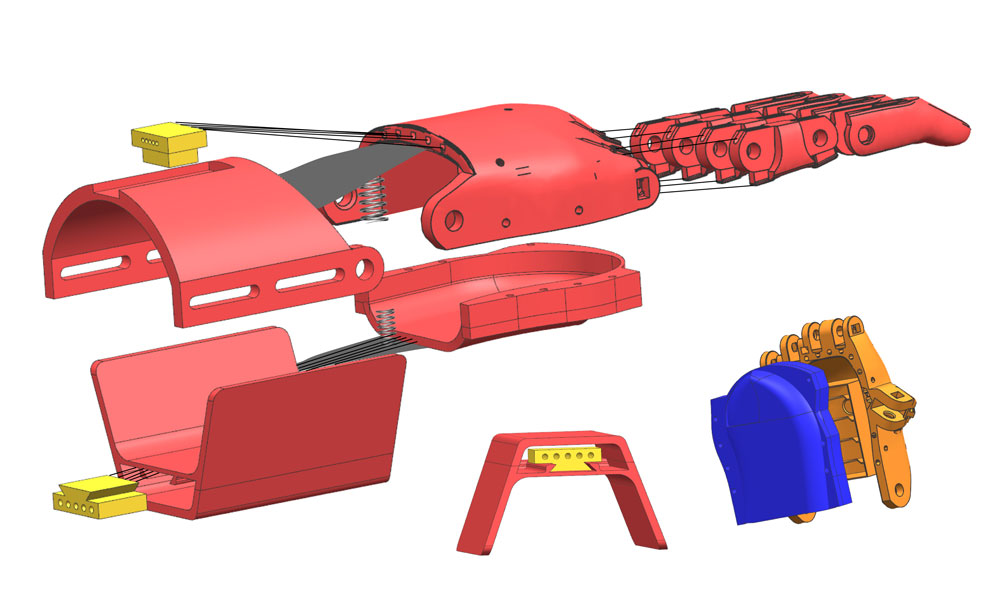

Given a basic CAD model of a prosthetic arm, we were tasked with figuring out the mechanism for flexion and extension. I researched and brainstormed different means of movement and communicated with the mentors and judges at the competition for feedback on the ideas.

Once we agreed on a solid idea of our mechanism, I created the CAD models on NX Siemens, 3D printed the pieces, and assembled the pieces using aluminum, velcro, and fishing line.

The fishing line threaded from the fingers to the wrist provides tension to allow for both flexion and extension. We created and presented our comfortable and lightweight prosthetic arm, and won a $500 prize.